Extrusion Presses

Features:

Hydraulic type extrusion presses available in various capacities as per customers requirements upto 2000 Tons.

Special purpose vertical extrusion press designed for silver alloy contacts and bi-metal bonding. ]

Simplified electrical controls for ease of maintenance.

Cylinders with extra long guides and robust design. Approach cylinders for fast cycle.

Modular type simplified powerpack design using cartridge valves with oil cooler as standard equipment for long life and ease of maintenance.

Optional accessories like die loader assembly, automatic biller loader and piercing cylinders can be provided as required.

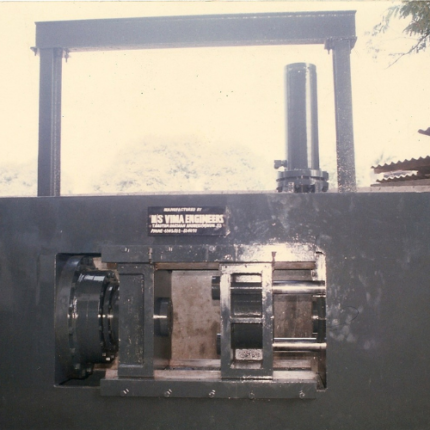

Forging Presses

Features:

Hydraulic type forging presses available in various sizes and capacities as per customers requirements upto 2000 Tons.

Available in H-type fabricated design as well as 4-column type designs.

Simplified electrical controls for ease of maintenance.

Compound cylinders for capacities upto 150 T which results in higher speeds of approach and return and dual speed pressing. Pressing speed doubles for smaller load jobs on same machine.

Higher capacity machine cylinders with extra long guides and robust design.

Modular type simplified powerpack design using lowering modules and cartridge valves with oil cooler as standard equipment for long life and ease of maintenance.

Ejection cylinder as standard feature. Material handing system and top ejection can be provided if required.

Also available in 8 point gib guided type with pre-stressed tie-rods.

FRP Manhole Cover Molding Presses

Features:

Hydraulic type FRP manhole cover molding machines are available in various sizes and capacities. These machines are used in hand lay up type operation.

Available in H-type fabricated design.

Powerpacks for operating the machines are sold separately. Each powerpack can operate multiple machines as required.

Rigid fabricated and machined Ram table and bottom head for optimal and uniform load application.

Four Nos. guides for the ram table ensures very less tilting of the ram table during pressing.

Hydraulic Cylinders

Features:

Vima Engineers has been manufacturing precision quality, high- end cylinders for all applications for the past three decades of capacities up to 2000 Tons. The experience we have gained has helped us in providing better quality cylinders consistently. Our customers can count on us to provide good quality materials, precision machining and quality control that remain the backbone of providing good quality cylinders.

Vima Engineers manufactures the “Goldline” line of hydraulic cylinders especially for machine tools applications. These cylinders are designed and developed to maintain a perfect balance of quality and costs. They are readily available in stock and have an excellent life.

All Vima cylinders are made out of cold drawn seamless pipes of various diameters. The cylinder pipes are duly bored and honed for high precision and excellent life. The pistons are one piece and wide surfaced to withstand the high loads and impact during operations. The piston rods are made out of EN8 rounds and are duly ground and hard chrome plated. The seals are dependent on the application; in general high-pressure seals are provided but we also provide special high-grade material seals such as PTFE, Bronze filled PTFE, polyurethane and viton rubber seals for high temperature operations. Gunmetal guide bush are provided on the piston as well as the guide flange wherever necessary.

Cylinders of all possible constructions can be manufactured. Special purpose type compound cylinders and cylinders with special cushion arrangements are also available in our extensive range for all types of applications. Servo cylinders can also be made available for special applications.

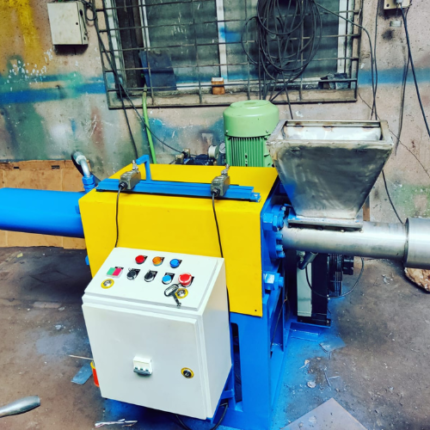

Hydraulic Power Packs

Features:

Hydraulic power units are the backbone of every hydraulic system or machinery. Vima Engineers designs and manufactures state of the art hydraulic power packs for all applications. We have designed and manufactured power packs upto 150 HP capacities.

Hydraulic power packs manufactured by us are assembled incorporating pumps/ valves of reputed manufacturers. Pump motor assemblies are mostly vertical mounted on tank top; In case of dual pump or triple pump circuit the pumps are connected to each other using extension brackets. All hydraulic valves are mounted on special manifold blocks such that piping is reduced and the unit is more compact. Oil tanks are made of MS sheets with necessary accessories. Different valves are used for different applications including manual, solenoid operated and also state of the art proportional solenoid operated valves. The power packs are designed keeping in mind workability, ease of maintenance, excellent life and aesthetic look as well. We always strive to design powerpacks which utilize minimal power and therefore are very efficient and low cost in the long run. We have also developed special low noise power packs using special oil immersed motors. These are specially used for hydraulic lifting systems and applications where low noise level is highly desirable.

Vima Engineers power packs are extensively used in steel mill applications, slitting lines, shearing lines, machine tools, marine applications, power compacting machines, press operations, testing equipment, extrusion plants, and more. Their digital presence — developed in collaboration with Seamerk, a Vasai-based website development agency — ensures that industrial buyers can easily access product specifications and connect with their engineering team.

Jewellery Hydraulic Press

Features:

Goldsmith hydraulic presses available in various capacities from 5T to 30T and higher as required.

High speed machines with upto 80 stks/min suitable for progresive dies.

Solid cylinder construction for zero leakage and long life. Special PTFE seals for high speed operation and long life.

Compact powerpack design with double pump for higher capacities to reduce motor HP and heating issues.

Higher capacities also provided with air-oil cooler to maintain the temperature of the oil.

Quality electrical components to increase life span of the machine.

Powder Compaction Presses

Vima engineers manufacture both static die-type and floating die-type powder compacting machines. The presses are either in fabricated two-column type or 4-column type tie rod design. PLC operation is standard in these presses. Power packs can be manufactured to accommodate special production requirements of individuals.

Salient Features of Powder Compacting:

- Heavy duty cylinders having extra long gun metal guide bushes and polyurethane type seals for longer life

- Specially designed electrical circuit using PLC system as standard

- Fine stroke adjustment device

- Modular design of power packs with the use of cartridge valves for higher capacities

- Oil cooler as standard

- Fully stress-relieved structure for higher capacities

Product Specifications

| Power Source | Hydraulic |

| Voltage | 380 V |

| Country of Origin | Made in India |

| Capacity | 60 Ton |

| Material | Mild Steel |

| Usage/Application | Industrial |

| Automatic Grade | Automatic |

Rubber Molding Presses

Features:

Rubber molding machines are available in various sizes and capacities as per customer requirements.

Available in H-type fabricated designs as well as 4-column type designs.

PLC controls are standard in automatic-type machines. Also available in manual operation.

Solid cylinder design with approach cylinders for fast opening and closing.

Modular-type, simplified powerpack design for long life and ease of maintenance.

Single Action Deep Drawing Press

Features:

Hydraulic type single action deep drawing pressesavailable in various sizes and capacities as per customers requirements upto 2000 Tons.

Available in H-type fabricated design as well as 4-column type designs.

Simplified electrical controls for ease of maintenance.

Compound cylinders for capacities upto 150 T which results in higher speeds of approach and return and dual speed pressing. Pressing speed doubles for smaller load jobs on same machine.

Higher capacity machine cylinders with extra long guides and robust design. Approach cylinders for fast opening and closing.

Modular type simplified powerpack design using lowering modules and cartridge valves with oil cooler as standard equipment for long life and ease of maintenance.

Knock-out bar assembly available as optional along with hydraulic top ejection system. Cushion cylinders can be provided as double acting type if required.

SMC Molding Presses

We offer SMC Molding Press. The offered array is designed and manufactured with the help of high quality basic materials and techniques.

Product Specifications

| Capacity | 1000 Ton |

| Power | 18.5 kW |

| Country of Origin | Made in India |

| Automation Grade | Automatic |

| Stroke | 300 mm |

| Voltage | 220 V |

| Material | Mild Steel |

| Brand | Vima Engineers |

Special Purpose Machines

Features:

Hydraulic type single action deep drawing pressesavailable in various sizes and capacities as per customers requirements upto 2000 Tons.

Available in H-type fabricated design as well as 4-column type designs.

Simplified electrical controls for ease of maintenance.

Compound cylinders for capacities upto 150 T which results in higher speeds of approach and return and dual speed pressing. Pressing speed doubles for smaller load jobs on same machine.

Higher capacity machine cylinders with extra long guides and robust design. Approach cylinders for fast opening and closing.

Modular type simplified powerpack design using lowering modules and cartridge valves with oil cooler as standard equipment for long life and ease of maintenance.

Knock-out bar assembly available as optional along with hydraulic top ejection system. Cushion cylinders can be provided as double acting type if required.

Static Die

Features:

Static Die type hydraulic powder compacting machines are available in various sizes and capacities.

Static Die type machines are used for all types of powder metallurgy operations which employ bi axial pressing or pressing from both sides.

Available in H-type fabricated design as well as 4-column type designs.

PLC as standard for electrical control panel.

Compound cylinders for capacities upto 150 T which results in higher speeds of approach and return and dual speed pressing. Pressing speed doubles for smaller load jobs on same machine.

Modular type simplified powerpack design using lowering modules and cartridge valves with oil cooler as standard equipment for long life and ease of maintenance.

Availabe with pneumatic/Hydraulic or servo feeders, multi platen type machines and also with servo package for precise setting of fill height and pressing height.